Engineered for ultimate performance, precision, and reliability.

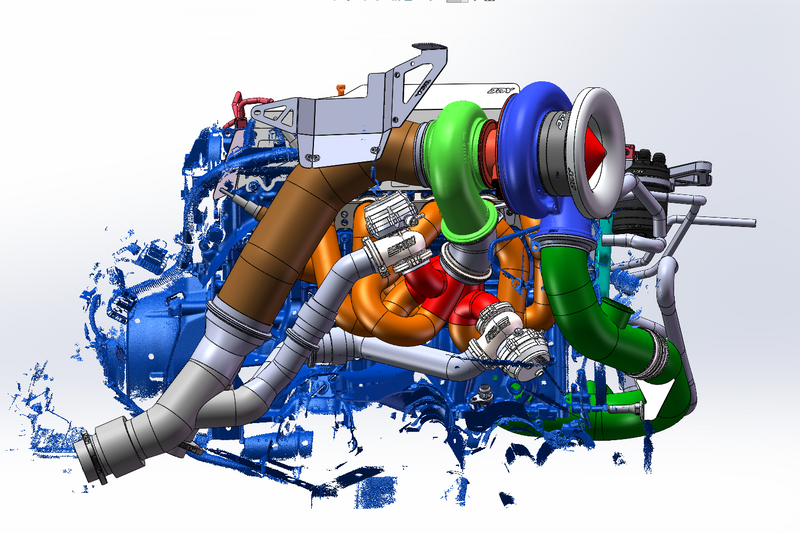

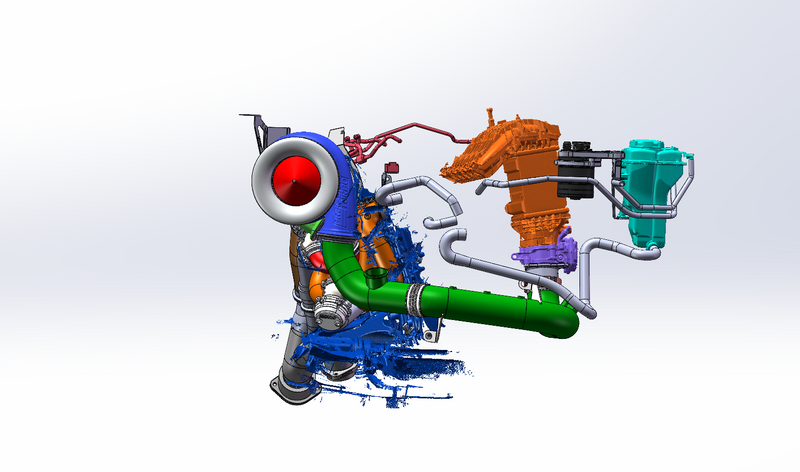

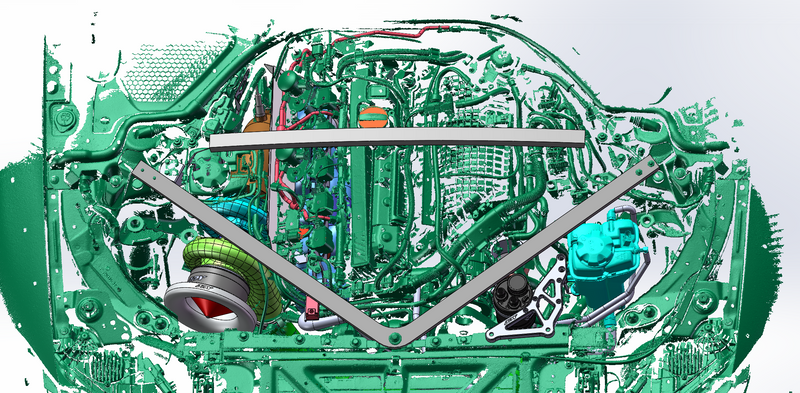

The JDY BMW G8X Single Turbo Kit – LHD is purpose-built for the BMW G8X M2, M3, and M4 platforms, delivering unmatched horsepower potential, efficiency, and durability. Designed with premium materials and verified by advanced simulation testing, this kit sets a new benchmark for single-turbo conversions.

Key Features & Technical Highlights

Exhaust Manifold (316 Stainless Steel)

-

CNC-machined one-piece 6-port flange.

-

Constructed from 42mm OD / 36mm ID and 48mm OD / 42mm ID 316 stainless tubing (3 mm wall).

-

Two runner sizing options provide flexibility:

-

Small ID → faster spool and response.

-

Large ID → higher peak horsepower.

-

-

Equal-length manifold design ensures balanced flow and improved turbo efficiency.

-

Welded with Fronius TIG equipment, using dual-sided argon shielding for maximum strength and reliability.

-

Verified via ANSYS fluid dynamics testing for optimized gas flow and durability.

Turbo Compatibility

-

42MM Version supports all Precision Turbo T4 sized(6670/6870/7275/7675) turbochargers.

-

48mm version is compatible with Precision Turbo 6870, 7275, 7675, 7480 Sportsman, 8085 Sportsman, and 8385 Sportsman models via a special manifold adaptor.

Exhaust Sealing & Hardware

-

Solid copper manifold gasket replaces OEM MLS for superior sealing.

-

Upgraded reinforced V-band clamps for durability under extreme pressure and heat.

Downpipe (304 Stainless Steel)

-

4-inch OD, 2 mm wall stainless steel, dual-section A/B design for easier install.

-

Fully welded inside and out, with dual-sided argon shielding.

-

Compatible with OEM and aftermarket mid-pipes.

-

Additional O2 bung for wideband sensors, with OEM O2 sensor provisions included.

Wastegate & Boost Control

-

Dual Precision Turbo 46mm dual-port wastegates (LHD version).

-

Choice option of internal dump and external dump exhaust routing(Screamer pipe ).

Oil & Water Lines

-

Feed line: Stainless steel AN4 swivel fittings, PTFE core, stainless braided exterior.

-

Return line: Upgraded to PTFE core piping, with aluminum AN10 fittings, black hard-anodized finish.

-

All lines covered with fire-resistant thermal sleeves.

-

CNC-machined aluminum fittings and flanges, anodized black for strength and longevity.

Coolant Relocation & Catch Can Integration

-

CNC-machined aluminum coolant relocation bracket, specifically designed to also accommodate the JDY oil catch can system.

-

Includes all necessary brackets, hoses, bolts, quick-connects, and wiring adapters for a seamless plug-and-play relocation.

-

Aftermarket engine oil catch can is required for this kit. JDY’s dedicated catch can system is available as an optional add-on.

Charge Piping & Clamps

-

3-inch aluminum charge pipes, fully TIG welded inside and out, hard-anodized finish.

-

All connections feature JDY Fast-Release Wiggins Clamps – no silicone couplers required.

-

CNC-machined billet throttle body flange replaces OEM plastic unit.

Intake System

-

CNC-machined aluminum velocity stack for optimized airflow.

-

Includes performance cotton filter and optional silicone coupler for different setups.

Heat Management

-

Custom 304 stainless steel heat shields protecting the plastic valve cover, firewall, and electrical connections.

-

Exhaust housing, turbo manifold, downpipe, and wastegate dump pipes coated with ceramic thermal barrier (same tech used in race pistons).

-

Enhanced heat protection ensures long-term reliability of OEM wiring and components.

Fuel System Safety – High Pressure Line Upgrade

-

Proprietary JDY redesign reroutes OEM high-pressure fuel line away from turbine housing.

-

Designed for 350 bar operating pressure (tested at 450 bar).

-

Eliminates vapor lock risk from fuel overheating – a unique JDY-exclusive safety feature.

Materials Overview

-

Exhaust Manifold: 316 Stainless Steel

-

Downpipe: 304 Stainless Steel

-

Charge Piping: Aluminum Alloy (Hard-Anodized)

-

Oil & Water Lines: PTFE Core with Stainless Braiding & Aluminum AN Fittings

-

Coolant Hoses: Reinforced Silicone with Braided Mesh

-

Heat Shields: 304 Stainless Steel

Why Choose JDY?

-

CAD-designed and ANSYS fluid-tested for performance validation.

-

Race-proven welding and fabrication standards.

-

OEM-plus fitment: Designed for direct compatibility with factory and aftermarket systems.

-

Unmatched power flexibility: Compatible with multiple Precision Turbo options for 800–1600+ HP builds.

-

Reliability first: Every component engineered to withstand the extreme demands of both track and street use.

Engineered for ultimate performance, precision, and reliability.

The JDY BMW G8X Single Turbo Kit – LHD is purpose-built for the BMW G8X M2, M3, and M4 platforms, delivering unmatched horsepower potential, efficiency, and durability. Designed with premium materials and verified by advanced simulation testing, this kit sets a new benchmark for single-turbo conversions.

Key Features & Technical Highlights

Exhaust Manifold (316 Stainless Steel)

-

CNC-machined one-piece 6-port flange.

-

Constructed from 42mm OD / 36mm ID and 48mm OD / 42mm ID 316 stainless tubing (3 mm wall).

-

Two runner sizing options provide flexibility:

-

Small ID → faster spool and response.

-

Large ID → higher peak horsepower.

-

-

Equal-length manifold design ensures balanced flow and improved turbo efficiency.

-

Welded with Fronius TIG equipment, using dual-sided argon shielding for maximum strength and reliability.

-

Verified via ANSYS fluid dynamics testing for optimized gas flow and durability.

Turbo Compatibility

-

42MM Version supports all Precision Turbo T4 sized(6670/6870/7275/7675) turbochargers.

-

48mm version is compatible with Precision Turbo 6870, 7275, 7675, 7480 Sportsman, 8085 Sportsman, and 8385 Sportsman models via a special manifold adaptor.

Exhaust Sealing & Hardware

-

Solid copper manifold gasket replaces OEM MLS for superior sealing.

-

Upgraded reinforced V-band clamps for durability under extreme pressure and heat.

Downpipe (304 Stainless Steel)

-

4-inch OD, 2 mm wall stainless steel, dual-section A/B design for easier install.

-

Fully welded inside and out, with dual-sided argon shielding.

-

Compatible with OEM and aftermarket mid-pipes.

-

Additional O2 bung for wideband sensors, with OEM O2 sensor provisions included.

Wastegate & Boost Control

-

Dual Precision Turbo 46mm dual-port wastegates (LHD version).

-

Choice option of internal dump and external dump exhaust routing(Screamer pipe ).

Oil & Water Lines

-

Feed line: Stainless steel AN4 swivel fittings, PTFE core, stainless braided exterior.

-

Return line: Upgraded to PTFE core piping, with aluminum AN10 fittings, black hard-anodized finish.

-

All lines covered with fire-resistant thermal sleeves.

-

CNC-machined aluminum fittings and flanges, anodized black for strength and longevity.

Coolant Relocation & Catch Can Integration

-

CNC-machined aluminum coolant relocation bracket, specifically designed to also accommodate the JDY oil catch can system.

-

Includes all necessary brackets, hoses, bolts, quick-connects, and wiring adapters for a seamless plug-and-play relocation.

-

Aftermarket engine oil catch can is required for this kit. JDY’s dedicated catch can system is available as an optional add-on.

Charge Piping & Clamps

-

3-inch aluminum charge pipes, fully TIG welded inside and out, hard-anodized finish.

-

All connections feature JDY Fast-Release Wiggins Clamps – no silicone couplers required.

-

CNC-machined billet throttle body flange replaces OEM plastic unit.

Intake System

-

CNC-machined aluminum velocity stack for optimized airflow.

-

Includes performance cotton filter and optional silicone coupler for different setups.

Heat Management

-

Custom 304 stainless steel heat shields protecting the plastic valve cover, firewall, and electrical connections.

-

Exhaust housing, turbo manifold, downpipe, and wastegate dump pipes coated with ceramic thermal barrier (same tech used in race pistons).

-

Enhanced heat protection ensures long-term reliability of OEM wiring and components.

Fuel System Safety – High Pressure Line Upgrade

-

Proprietary JDY redesign reroutes OEM high-pressure fuel line away from turbine housing.

-

Designed for 350 bar operating pressure (tested at 450 bar).

-

Eliminates vapor lock risk from fuel overheating – a unique JDY-exclusive safety feature.

Materials Overview

-

Exhaust Manifold: 316 Stainless Steel

-

Downpipe: 304 Stainless Steel

-

Charge Piping: Aluminum Alloy (Hard-Anodized)

-

Oil & Water Lines: PTFE Core with Stainless Braiding & Aluminum AN Fittings

-

Coolant Hoses: Reinforced Silicone with Braided Mesh

-

Heat Shields: 304 Stainless Steel

Why Choose JDY?

-

CAD-designed and ANSYS fluid-tested for performance validation.

-

Race-proven welding and fabrication standards.

-

OEM-plus fitment: Designed for direct compatibility with factory and aftermarket systems.

-

Unmatched power flexibility: Compatible with multiple Precision Turbo options for 800–1600+ HP builds.

-

Reliability first: Every component engineered to withstand the extreme demands of both track and street use.