7Product Overview

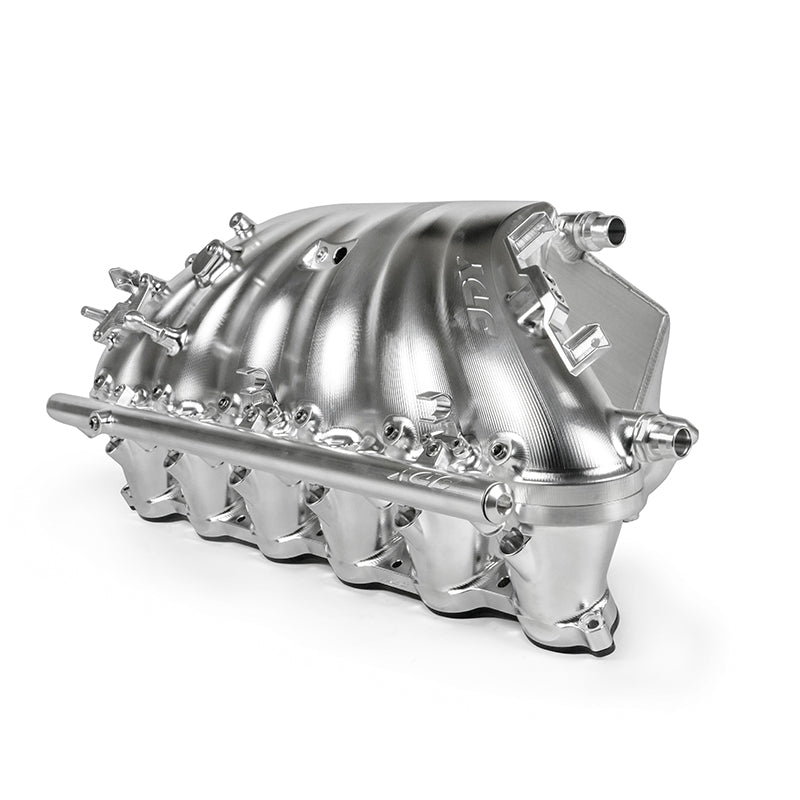

The JDY S58 intake manifold is a fully CNC-machined billet aluminum intake system developed specifically for BMW S58 engines.

Unlike conventional aftermarket designs that focus solely on volume increase, JDY’s intake manifold was engineered with airflow uniformity, structural consistency, and real-world serviceability as the primary objectives.

Through extensive CFD analysis, multiple internal airflow configurations, and quantitative comparison testing, JDY delivers an intake manifold that not only increases plenum volume significantly, but also actively improves cylinder-to-cylinder airflow balance, addressing a known limitation of the S58 intake layout.

Core Engineering Advantages

-1, Largest Plenum Volume with One-Piece CNC Construction

JDY features the Custom lARGEST plenum volume currently available for the S58 platform (5250cc), representing:

- +62.4% vs OEM

- +30% vs most other competitors aftermarket designs

More importantly, the plenum is fully CNC-machined as a single structural assembly and maintain at 4mm wall thickness, rather than fabricated from multiple thin-wall components.

Advantages:

- Higher structural rigidity under high boost

- Better dimensional consistency between units

- Cleaner internal airflow surface to minimize air drag

- Superior long-term durability.

- by the shape of the plenum, cooled air is evenly distributed to each cylinder.

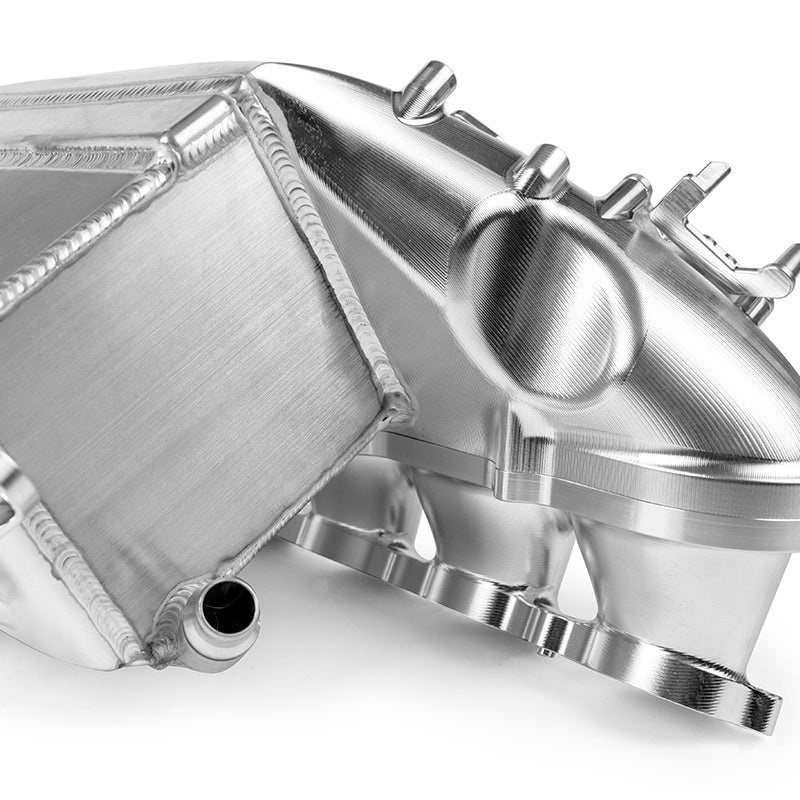

-2, Solving Throttle Offset Airflow Imbalance (CFD-Driven Design)

Due to the throttle body being offset from the centerline of the intake manifold on the S58 engine, uneven airflow distribution between in the cooler and between cylinders is inevitable in traditional designs.

JDY addressed this issue by:

- Performing CFD simulations on multiple internal guide plate designs

- Comparing airflow velocity vectors, velocity contour maps, and outlet uniformity

- Quantifying airflow balance using Surface Uniformity Index

After testing multiple configurations, JDY uses guide plate geometry that achieved the highest airflow uniformity index (0.880), compared to 0.781 in the original non-guided design.

Results in:

- More uniform airflow distribution across heat exchanger

- Reduced peak velocity concentration

- Improved charge consistency at high RPM and boost

- Enhanced reliability for high-output applications

Each airflow guide plate is fully CNC-machined from aluminum, and precisely welded at the proper angle, it provides a durable and consistant performance.

-3,Modular Runner Design for Scalable Fueling

The JDY intake manifold adopts a modular runner architecture, allowing the runner section to be replaced independently.

This enables:

- Single MPI (one injector per cylinder)

- Dual MPI (two injectors per cylinder) (WORLD First & NO.1 to date !!!!!)

Advantages:

- Interchangable lower upgrade cost for future power goals

- Flexible fueling strategies without replacing the entire manifold/cooler

- Ideal for staged builds from street to race

-4, Integrated High-Flow Fuel Rail System

To support high fuel demand applications, JDY integrates the fuel rail directly into the manifold structure:

- Single MPI version: AN8-ORB integrated fuel rail

- Dual MPI version: Enlarged AN10-ORB integrated fuel rail

Additional features:

- One 1/8 NPT port on fuel rail- can be used for any type of fuel pressure sensor.

- Compatible with Bosch EV14 style injectors (Injector dynamics, FIC and etc )

- Unused injector ports can be blocked with supplied plugs

- This integrated design reduces leak points while improving fuel delivery stability.

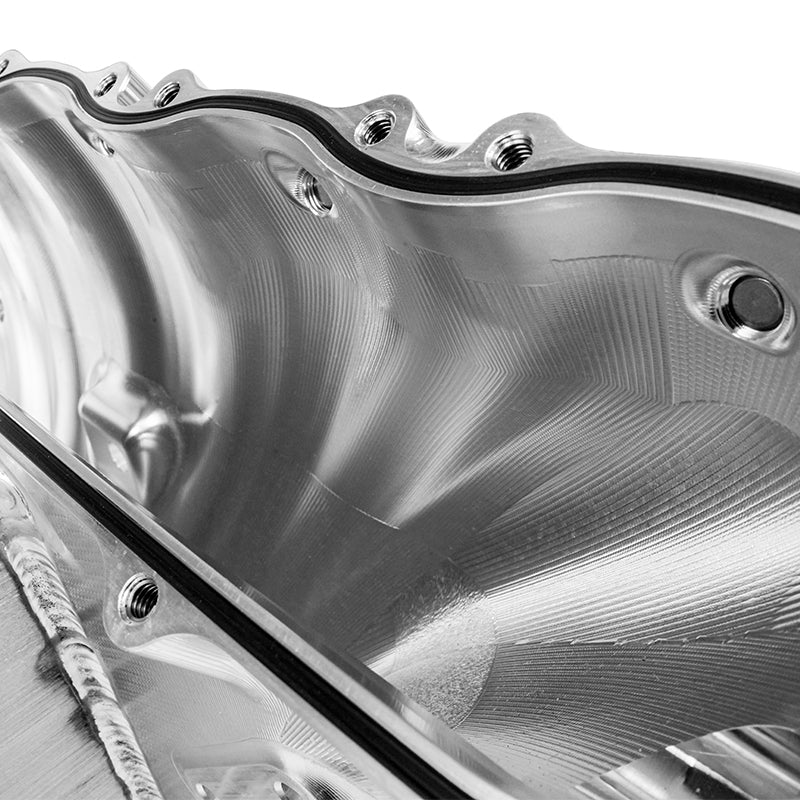

-5, Low internal surface roughness

Compared to welded or fabricated structures, the JDY intake manifold offers significantly lower and more consistent internal surface roughness, reducing flow separation and pressure loss within the intake path

This optimized surface condition enhances airflow stability and volumetric efficiency, particularly under high-load operating conditions.

-6, OEM-Level Fitment & Serviceability

Despite the significantly increased plenum size, JDY maintains full OEM compatibility with brackets and fitting provided, including:

- OEM coolant hose routing

- OEM EVAP system support (with optional delete plugs)

- Engine cover installation retained

- Coolant expansion tank retained

- Oil filter access fully preserved

- Redesigned CNC aluminum wiring brackets included

This ensures the intake manifold is suitable not only for race builds, but also for high-end street cars requiring OEM-level service convenience.

For tuning and Nitrous/ WMI purposese, there are :

- there are 2 extra bottom-mounted NPT ports for boost source, MAP sensor, or other NPT purposes.

- 6* top-mounted NPT ports for methanol, nitrous, and sensors

-7,Advanced Thermal Isolation & High-Pressure Sealing

JDY supplies a custom-developed cylinder head thermal isolation gasket, featuring:

- Thermal conductivity: 0.25–0.27 W/(m·K)

- Compared to 6061-T6 aluminum: ~167 W/(m·K), Continuous operating temperature up to 250°C

This material avoids the cracking, deformation, and carbonization risks associated with common phenolic spacers.

Additionally, the manifold and plenum utilize:

- X-profile FKM (Viton) sealing rings

- Male-female stepped sealing interface

- This structure provides superior sealing performance under high boost and pressure fluctuations.

-8, Stainless Steel Thread Sleeve for Lifetime Durability

High-performance intake systems are frequently installed, removed, and serviced over the vehicle’s lifetime — especially on track and race cars.

To ensure long-term durability and consistent clamping force, JDY integrates three stainless steel thread sleeve directly into the aluminum plenuim to runner flange.

- Unlike bare aluminum threads, stainless steel inserts provide:

- Significantly increased thread strength

- Resistance to wear, galling, and thread pull-out

- Stable torque retention after repeated installation cycles

This design ensures reliable, damage-free installation over the lifetime of the manifold, even under frequent service and high thermal loads.

Key Features

- 6061-T6 aluminum, full CNC-machined construction

- Largest S58 plenum volume on the market (5250cc)

- One-piece billet plenum for strength and consistency

- CFD-optimized internal airflow guide plate

- Proven improvement in airflow uniformity

- Interchangable modular runner design (single MPI / dual MPI)

- Integrated AN8 / AN10 high-flow fuel rail options

- Bosch EV14 injector compatibility

- 6* top-mounted NPT ports for methanol, nitrous, and sensors

- OEM mounting points and serviceability retained

- 2* bottom-mounted NPT ports for boost source, MAP sensor, or other NPT purposes.

- Stainless steel thread inserts at plenum to runner flange— built for repeated install & removal without thread failure

Vehicle Compatibility

-

LHD / RHD BMW M3 G80 Sedan

-

LHD / RHD BMW M3 G81 Touring

-

LHD / RHD BMW M4 G82 Coupe

-

LHD / RHD BMW M4 G83 Convertible

-

LHD / RHD BMW G87 M2 Coupe

-

LHD / RHD BMW F97 X3 M

-

LHD / RHD BMW F98 X4 M

7Product Overview

The JDY S58 intake manifold is a fully CNC-machined billet aluminum intake system developed specifically for BMW S58 engines.

Unlike conventional aftermarket designs that focus solely on volume increase, JDY’s intake manifold was engineered with airflow uniformity, structural consistency, and real-world serviceability as the primary objectives.

Through extensive CFD analysis, multiple internal airflow configurations, and quantitative comparison testing, JDY delivers an intake manifold that not only increases plenum volume significantly, but also actively improves cylinder-to-cylinder airflow balance, addressing a known limitation of the S58 intake layout.

Core Engineering Advantages

-1, Largest Plenum Volume with One-Piece CNC Construction

JDY features the Custom lARGEST plenum volume currently available for the S58 platform (5250cc), representing:

- +62.4% vs OEM

- +30% vs most other competitors aftermarket designs

More importantly, the plenum is fully CNC-machined as a single structural assembly and maintain at 4mm wall thickness, rather than fabricated from multiple thin-wall components.

Advantages:

- Higher structural rigidity under high boost

- Better dimensional consistency between units

- Cleaner internal airflow surface to minimize air drag

- Superior long-term durability.

- by the shape of the plenum, cooled air is evenly distributed to each cylinder.

-2, Solving Throttle Offset Airflow Imbalance (CFD-Driven Design)

Due to the throttle body being offset from the centerline of the intake manifold on the S58 engine, uneven airflow distribution between in the cooler and between cylinders is inevitable in traditional designs.

JDY addressed this issue by:

- Performing CFD simulations on multiple internal guide plate designs

- Comparing airflow velocity vectors, velocity contour maps, and outlet uniformity

- Quantifying airflow balance using Surface Uniformity Index

After testing multiple configurations, JDY uses guide plate geometry that achieved the highest airflow uniformity index (0.880), compared to 0.781 in the original non-guided design.

Results in:

- More uniform airflow distribution across heat exchanger

- Reduced peak velocity concentration

- Improved charge consistency at high RPM and boost

- Enhanced reliability for high-output applications

Each airflow guide plate is fully CNC-machined from aluminum, and precisely welded at the proper angle, it provides a durable and consistant performance.

-3,Modular Runner Design for Scalable Fueling

The JDY intake manifold adopts a modular runner architecture, allowing the runner section to be replaced independently.

This enables:

- Single MPI (one injector per cylinder)

- Dual MPI (two injectors per cylinder) (WORLD First & NO.1 to date !!!!!)

Advantages:

- Interchangable lower upgrade cost for future power goals

- Flexible fueling strategies without replacing the entire manifold/cooler

- Ideal for staged builds from street to race

-4, Integrated High-Flow Fuel Rail System

To support high fuel demand applications, JDY integrates the fuel rail directly into the manifold structure:

- Single MPI version: AN8-ORB integrated fuel rail

- Dual MPI version: Enlarged AN10-ORB integrated fuel rail

Additional features:

- One 1/8 NPT port on fuel rail- can be used for any type of fuel pressure sensor.

- Compatible with Bosch EV14 style injectors (Injector dynamics, FIC and etc )

- Unused injector ports can be blocked with supplied plugs

- This integrated design reduces leak points while improving fuel delivery stability.

-5, Low internal surface roughness

Compared to welded or fabricated structures, the JDY intake manifold offers significantly lower and more consistent internal surface roughness, reducing flow separation and pressure loss within the intake path

This optimized surface condition enhances airflow stability and volumetric efficiency, particularly under high-load operating conditions.

-6, OEM-Level Fitment & Serviceability

Despite the significantly increased plenum size, JDY maintains full OEM compatibility with brackets and fitting provided, including:

- OEM coolant hose routing

- OEM EVAP system support (with optional delete plugs)

- Engine cover installation retained

- Coolant expansion tank retained

- Oil filter access fully preserved

- Redesigned CNC aluminum wiring brackets included

This ensures the intake manifold is suitable not only for race builds, but also for high-end street cars requiring OEM-level service convenience.

For tuning and Nitrous/ WMI purposese, there are :

- there are 2 extra bottom-mounted NPT ports for boost source, MAP sensor, or other NPT purposes.

- 6* top-mounted NPT ports for methanol, nitrous, and sensors

-7,Advanced Thermal Isolation & High-Pressure Sealing

JDY supplies a custom-developed cylinder head thermal isolation gasket, featuring:

- Thermal conductivity: 0.25–0.27 W/(m·K)

- Compared to 6061-T6 aluminum: ~167 W/(m·K), Continuous operating temperature up to 250°C

This material avoids the cracking, deformation, and carbonization risks associated with common phenolic spacers.

Additionally, the manifold and plenum utilize:

- X-profile FKM (Viton) sealing rings

- Male-female stepped sealing interface

- This structure provides superior sealing performance under high boost and pressure fluctuations.

-8, Stainless Steel Thread Sleeve for Lifetime Durability

High-performance intake systems are frequently installed, removed, and serviced over the vehicle’s lifetime — especially on track and race cars.

To ensure long-term durability and consistent clamping force, JDY integrates three stainless steel thread sleeve directly into the aluminum plenuim to runner flange.

- Unlike bare aluminum threads, stainless steel inserts provide:

- Significantly increased thread strength

- Resistance to wear, galling, and thread pull-out

- Stable torque retention after repeated installation cycles

This design ensures reliable, damage-free installation over the lifetime of the manifold, even under frequent service and high thermal loads.

Key Features

- 6061-T6 aluminum, full CNC-machined construction

- Largest S58 plenum volume on the market (5250cc)

- One-piece billet plenum for strength and consistency

- CFD-optimized internal airflow guide plate

- Proven improvement in airflow uniformity

- Interchangable modular runner design (single MPI / dual MPI)

- Integrated AN8 / AN10 high-flow fuel rail options

- Bosch EV14 injector compatibility

- 6* top-mounted NPT ports for methanol, nitrous, and sensors

- OEM mounting points and serviceability retained

- 2* bottom-mounted NPT ports for boost source, MAP sensor, or other NPT purposes.

- Stainless steel thread inserts at plenum to runner flange— built for repeated install & removal without thread failure

Vehicle Compatibility

-

LHD / RHD BMW M3 G80 Sedan

-

LHD / RHD BMW M3 G81 Touring

-

LHD / RHD BMW M4 G82 Coupe

-

LHD / RHD BMW M4 G83 Convertible

-

LHD / RHD BMW G87 M2 Coupe

-

LHD / RHD BMW F97 X3 M

-

LHD / RHD BMW F98 X4 M